DIE CUTTING

Quick, low-cost cutting • Precision Shapes • Very Clean Cut

felt • rubber • leather • cardboard • paper • thin wood • thin plastic

APPLICATIONS

Die cutting is the fastest, most economical, and cleanest way to cut large quantities of smaller parts. A custom die must be produced for each shape or pattern.

SPECIFICATIONS

• max cut piece size: 60”x22"

• max material size: 72” wide x unlimited length

• max material thickness: about 1”

• See our CAD FILE PREP GUIDE

MATERIALS

Die cutting works best on pliable materials such as felt, rubber, leather, cardboard, or paper. Rigid materials like wood or plastic can be die cut if material thickness is less than 0.060”.

Each die-cut shape requires a custom cutting die or blade. Dies usually cost $50 to $500, depending on size and complexity, and take about a week to make. Please note that we do not sell cutting dies - we have them made for cutting services that we provide. After producing the die, cutting is usually about $0.50 to $1.00 per piece, depending on the material, part size, and quantity. Please see our CAD FILE PREP GUIDE for more information on submitting a file for a die-cutting project.

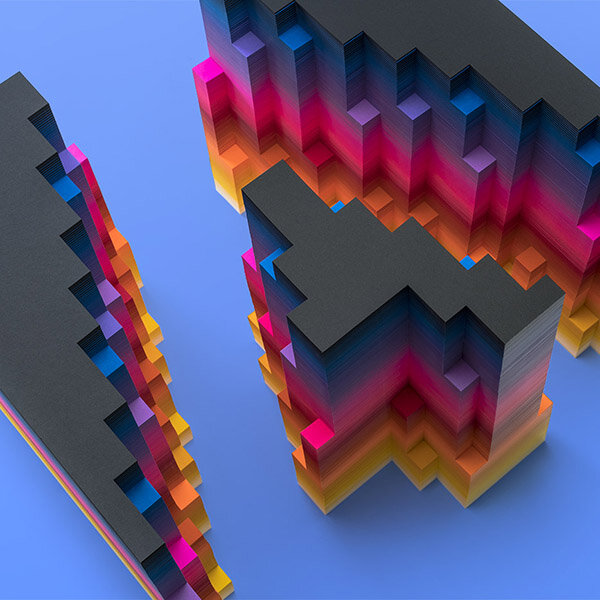

Die Cut Stacked Paper Sculpture

Die Cut Rubber Pads

Die Cut Foam Packaging

Wool Felt Hat Emblem

Die Cut Felt Leaves

Synthetic Felt Cacti

Wool Felt Tablet Sleeve

Custom Corrugated Packaging